Secure Remote Maintenance

The globalized world seems to go smaller every twenty-four hour period. Recent events offer a stark reminder, however, that the power to simply "hop on the next aeroplane" is fragile liberty not to be taken for granted. Beyond much of the globe, travel has been severely restricted or cut off entirely. Exist that as it may, OEMs still have machines in the field that need to exist deputed, serviced, and upgraded – and delays in response time are plush.

For nearly OEMs, aside from the occasional spare part or scheduled maintenance, contact with a motorcar ends at delivery. "Many car builders shy away from remote maintenance for fright it will be overly complicated or present a security hazard," says René Blaschke, product manager for IIoT at B&R. Remote maintenance often requires sensitive machine data to exist sent over the internet, which for many is reason enough for hesitation. Yet, every minute of downtime eats away at an operator'due south bottom line. Plush downtime can be kept to a minimum with remote maintenance.

Another concern of auto builders is that the time-intensive task of rolling out a complex digital maintenance solution would go along employees from their primary tasks. "That'southward why we made sure to create a solution that is very easy to implement," says Blaschke. Remote maintenance offers machine builders an enormous advantage – when they go the call, service technicians tin can connect to the machine quickly and resolve the issue.

Remote maintenance saves time and coin

With Secure Remote Maintenance from B&R, machine builders tin can perform system diagnostics remotely or install updates from a central location. "When they get the call, service technicians no longer have to hop on a plane. Instead, they can hop on their PC and connect digitally to the client's motorcar," says Blaschke. "Remote maintenance saves time and money."

In a few short steps, the B&R Remote Maintenance Solution is set, and technicians have like shooting fish in a barrel access to machines all over the world. "The SiteManager hardware just needs to exist connected to the machine controller. It and then establishes a remote maintenance tunnel to the central GateManager," explains Blaschke. Like all B&R hardware, the SiteManager tin can be configured using the Automation Studio engineering tool.

The technician tin establish a secure connection in moments and so run diagnostics, suit parameters and resolve any faults as though they were correct there on site. All access to the automobile is logged in detail and can be traced at any fourth dimension. The B&R SiteManager tin be factory installed on new machines or retrofitted on existing ones. In both cases, the solution is seamlessly integrated into the automation system.

State-of-the-art security

Secure communication is one of the nigh central challenges of remote maintenance. Transmitted motorcar data must be highly transparent, yet simultaneously absolutely secure. B&R's Secure Remote Maintenance has what it takes to guarantee a secure and reliable connexion. "Through a combination of state-of-the-art protocols, technologies, and infrastructure components, our solution ensures optimal protection," explains Blaschke. "The security standards used in remote maintenance are comparable to those used in online banking." Information is encrypted during transmission in order to foreclose hackers from accessing it.

"Our solution is optimally protected through modern protocols, technologies, and infrastructure components. The security standards are comparable to those used for online banking," says René Blaschke, product manager for IIoT at B&R.

When an incident occurs, the SiteManager sends the respective alarms, events, or status updates to the motorcar operator via text bulletin or email. These notifications are preconfigured directly via the remote maintenance hardware. This is an easy way to ensure transparent motorcar operation and that users e'er know the current condition of their manufacturing assets.

1 solution, many applications

Secure Remote Maintenance does more just maintenance – it can also be used to commission a machine remotely. When machine builders deliver equipment to their customers, they no longer need to dispatch a service technician halfway effectually the world to put it into performance. As before long as the SiteManager on the machine is configured, a connexion can be established and the automobile can be commissioned. Organization parameters software settings can be adapted to client's requirements.

Since updates can also exist installed remotely with Secure Remote Maintenance, machines and systems are ever up to date. A service technician can connect to the machine via the remote maintenance software and update a program or the firmware, for case. That drastically reduces the time and costs associated with keeping systems upward to date.

All of an OEM'southward machinery and equipment can be managed from a central location. This brings automobile builders closer to their customers and allows them to offer additional services with meaning added value. New business organisation models get possible, such equally monitoring the wellness and performance of manufacturing assets to optimize service intervals.

Secure connection to the cloud

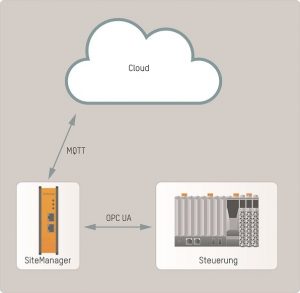

B&R'southward SiteManager transfers information securely to the deject. "The SiteManager connects to the machine controller via OPC UA and transfers information to the cloud using the MQTT bulletin protocol," explains Blaschke. The user defines which data is to exist transferred when configuring the solution. It is also possible to transfer different data to different deject providers. Configuration is completed easily in the SiteManager'south spider web-based user interface.

In improver to the cloud interface, various options are available for aggregated assay, such as adding of minimum, maximum and average values. An integrated store-and-forrard database ensures that no information is lost in the event of connection problems.

Fast service response fourth dimension

For OEMs, having customers around the world also comes with its share of new challenges. Maintenance work that can only be carried out with the help of the manufacturer is very resource intensive. "A remote maintenance solution removes that obstacle," says Blaschke. OEMs can connect to whatsoever nugget, anywhere in the field, at whatever time to keep their customers' systems running smoothly and efficiently. That saves time and coin for everyone involved.

Source: https://packagingsouthasia.com/packaging-production/secure-remote-maintenance/

0 Response to "Secure Remote Maintenance"

Post a Comment